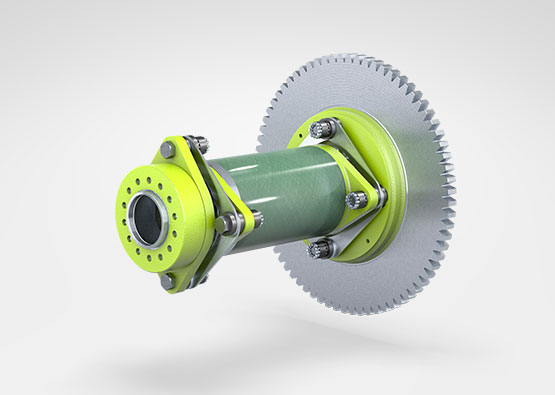

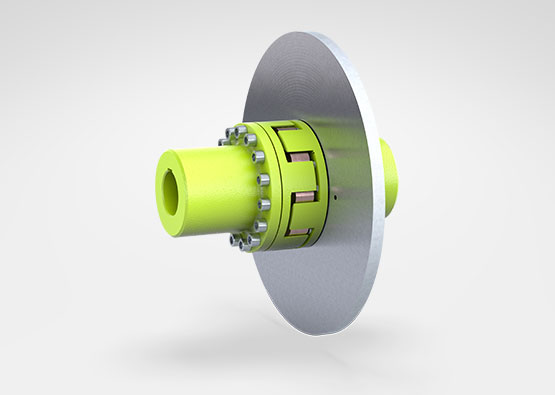

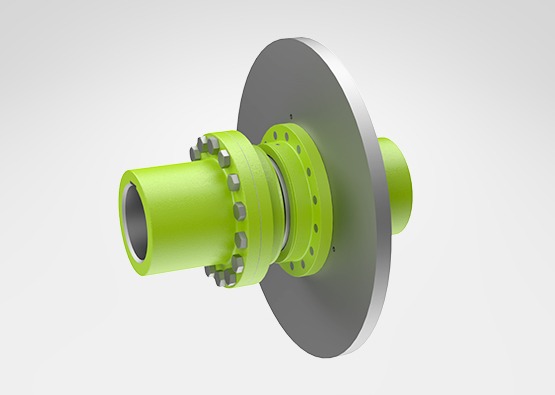

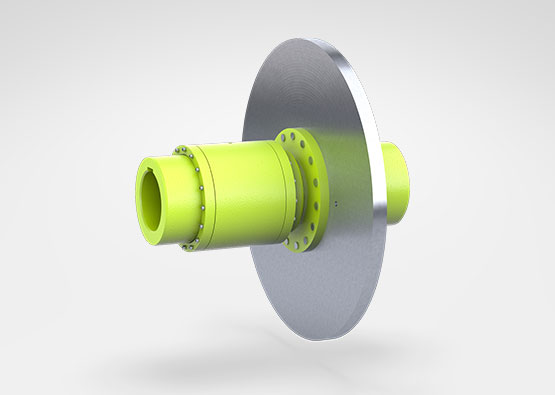

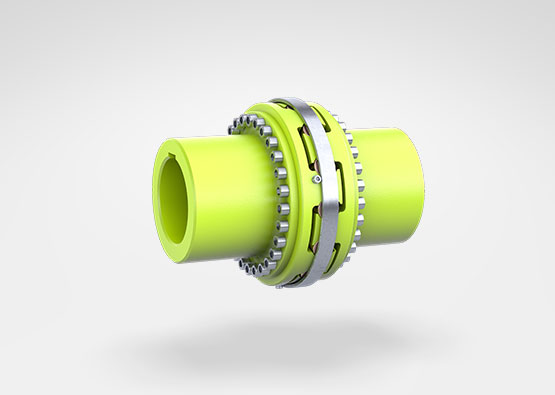

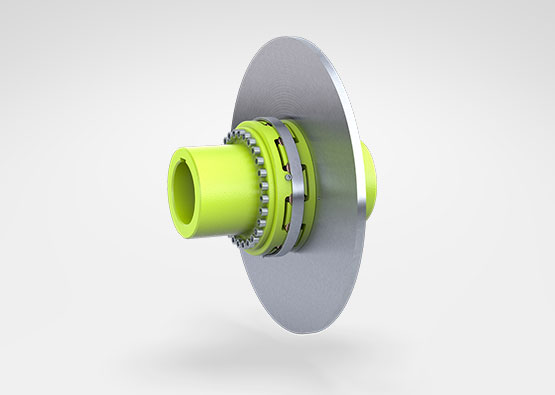

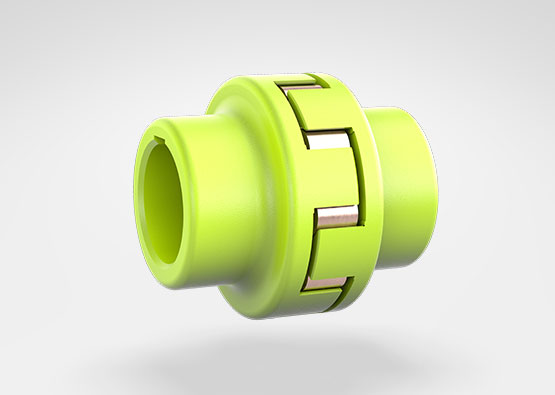

KBT

TKMAX: 46000 Nm

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

- Steel coupling with special tooth pattern

- Torque transmission via internal geared sleeve and external geared hubs

- Replacement of the brake disc or the seals without moving any equipment

- High temperature resistance

- Low wear

- Arrangement of the brake drum on the gear side to allow the brake torque to be maintained when the motor is disengaged

- Vast selection of coupling sizes and brake disc diameters

- Coupling hubs finish bored and keywayed acc. to DIN 6885

- Coupling hubs unbored

- Coupling hubs pilot bored

- Coupling dynamically balanced according to ISO 21940 Grade: G 2.5; G 6.3

- Hubs in special dimensions

- Hubs in special material

- Test certificate DIN EN 10204-3.1

Additional PRODUCTS

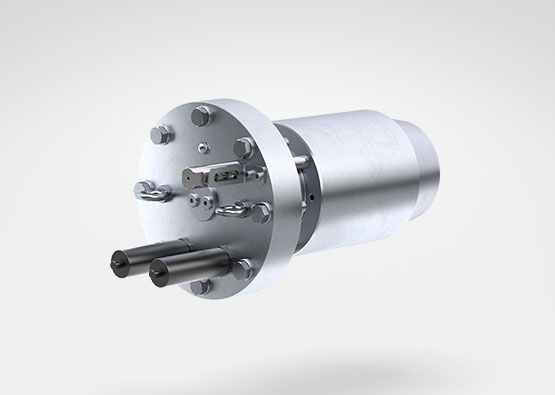

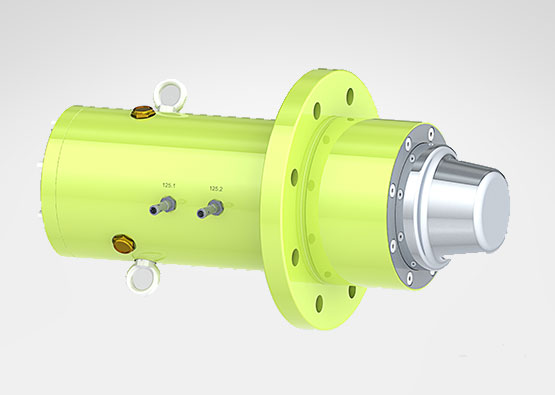

A hydraulic rotor lock offering up to 250 bar pressure with an activation time of 60 seconds.

We offer three models of the JHS-RLH-240 hydraulic rotor lock – the GL Type Certified JHS-RLH-240, the JHS-RLM-240 and the JHS-RLH-240-154. All these locks deliver up to 250 bar pressure with an activation time of just 35 seconds.

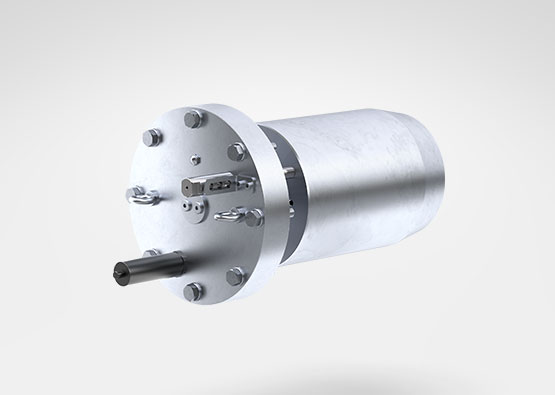

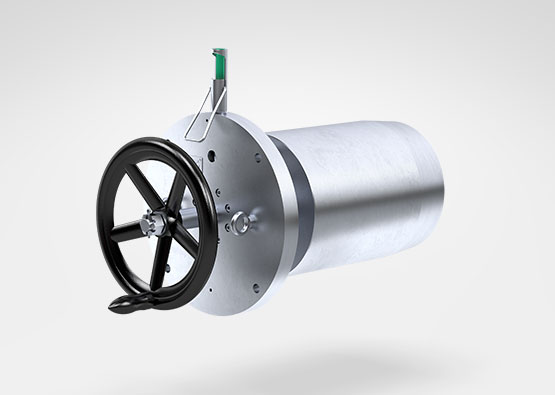

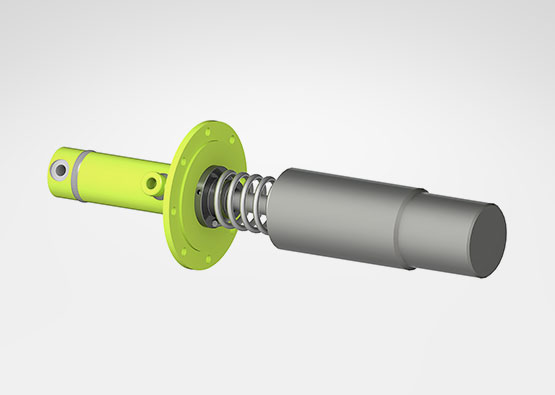

Manually activated rotor lock used for safety purposes during maintenance operations to stop the rotor mechanically. The maximum lateral force is 6400 N and the standard stroke is 95 mm. Other strokes are available upon request.

JHS WTC is a flexible disc coupling mounted between gearbox and generator. It's a tailor-made solution for wind turbine applications (Type WTC = Wind Turbine Coupling).

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

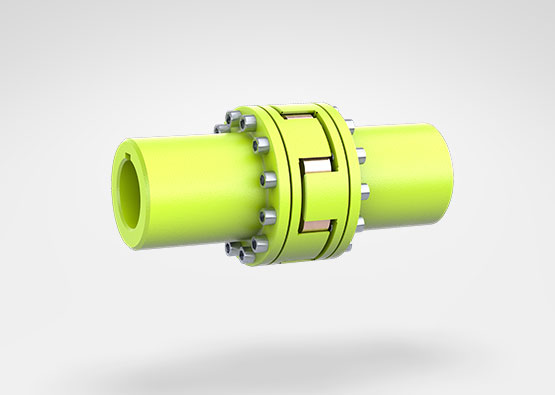

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

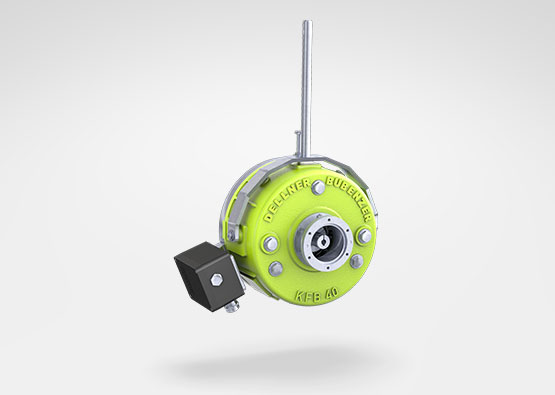

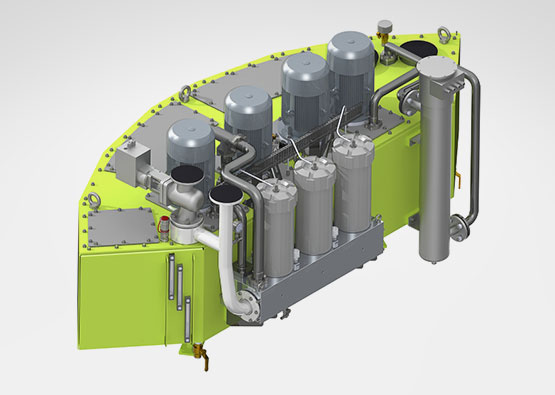

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

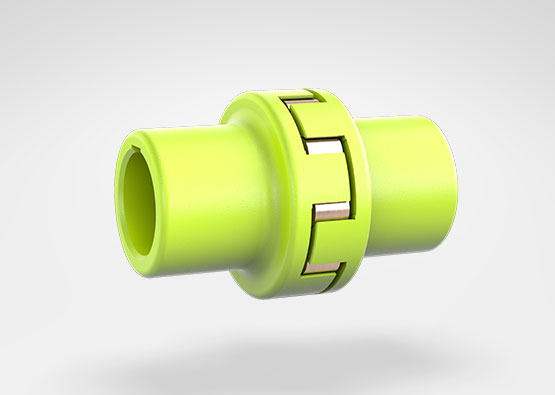

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.