K

- Torsional Force:

- 40050 Nm

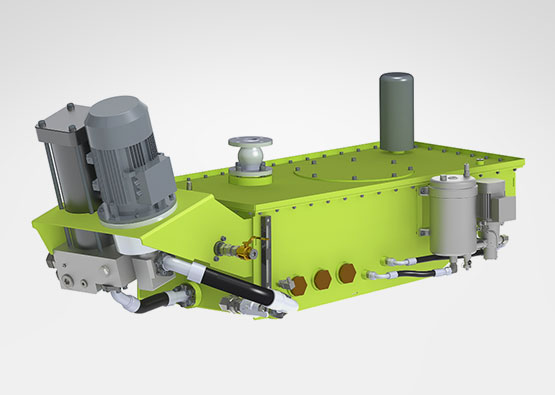

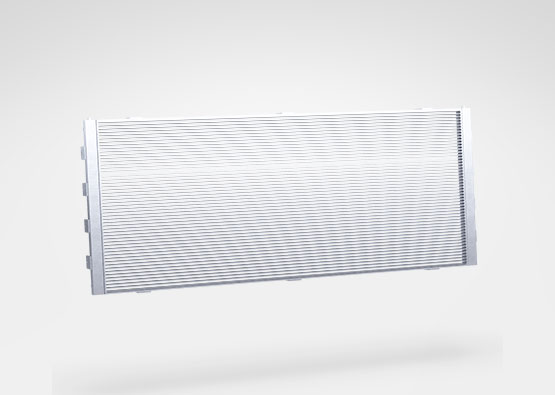

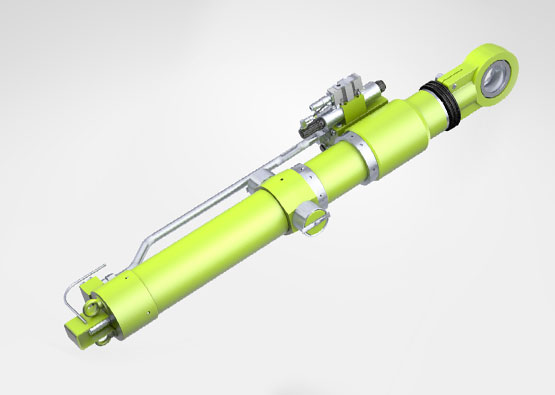

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type. The standard material of the elastic intermediate ring Polyurethane (Vulkollan) is suitable for a temperature range of -35°C up to +80°C. For a short time -40°C up to +100°C.

- Steel coupling, torsionally elastic and bullet-proof (fail safe)

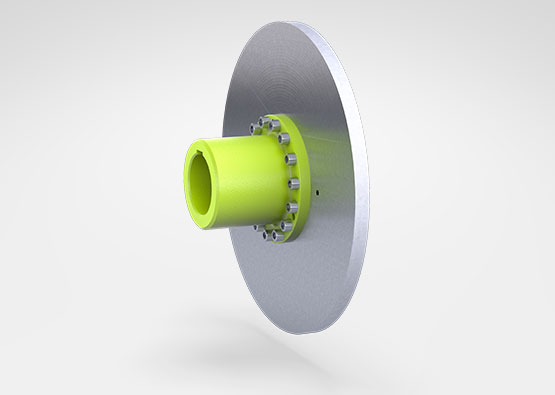

- Torque transmission via elastic intermediate ring

- Replacement of the elastic intermediate ring or the brake disc without moving any equipment

- Arrangement of the brake drum on the gear side to allow the brake torque to be maintained when the motor is disengaged

- Vast selection of coupling sizes and brake disc diameters

- Coupling hubs finish bored and keywayed

- acc. to DIN 6885

- Coupling hubs unbored

- Coupling hubs pilot bored

- Coupling dynamically balanced according to ISO 21940 Grade: G 2.5; G 6.3

- Coupling hubs in special lengths

- Coupling hubs in special material

- Test certificate DIN EN 10204-3.1

Additional PRODUCTS

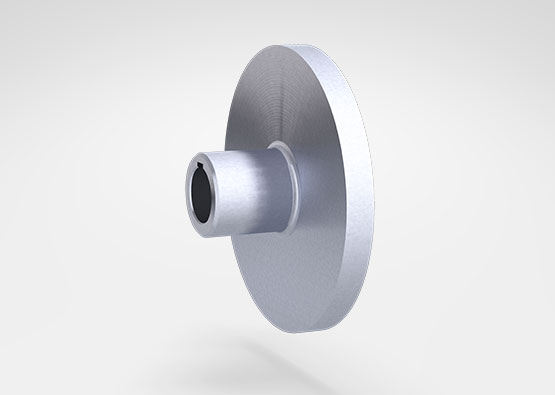

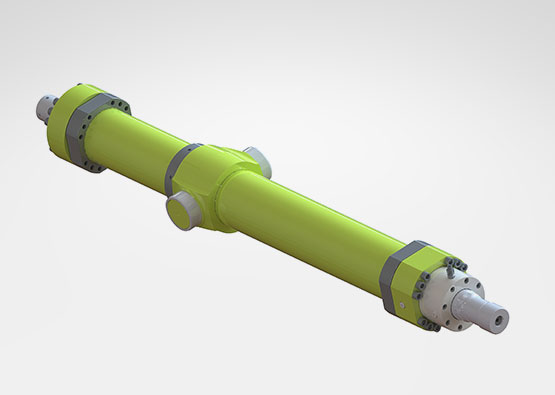

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

For many years a seawaterproof version of the SFB series has been used successfully on winch motors in ship building and as a safety, service or holding brake in wharf crane installations.