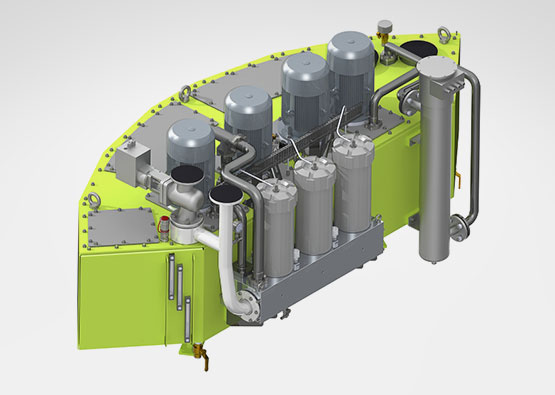

Hydraulic Power Unit

-

Model Number: B7329

- Customized designs, single and multiple motor/pump options

- Oil and pressure supply for hub pitch control hydraulics

- Designed and built for high cycle fatigue loading

- Hydraulic Crane, Rotor Lock and brake auxiliary functions

- Service and commissioning functions

- Redundant power output

- Operation down to -30°C and survival to -40°C

Additional PRODUCTS

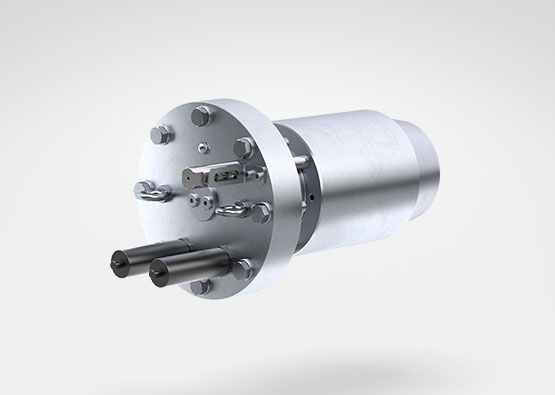

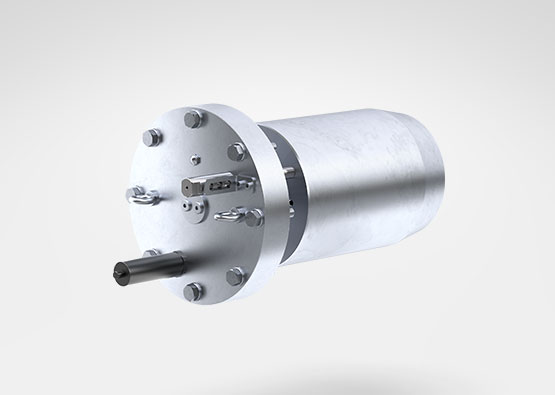

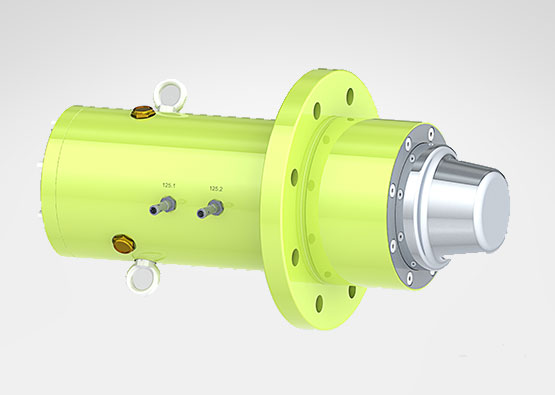

A hydraulic rotor lock offering up to 250 bar pressure with an activation time of 60 seconds.

We offer three models of the JHS-RLH-240 hydraulic rotor lock – the GL Type Certified JHS-RLH-240, the JHS-RLM-240 and the JHS-RLH-240-154. All these locks deliver up to 250 bar pressure with an activation time of just 35 seconds.

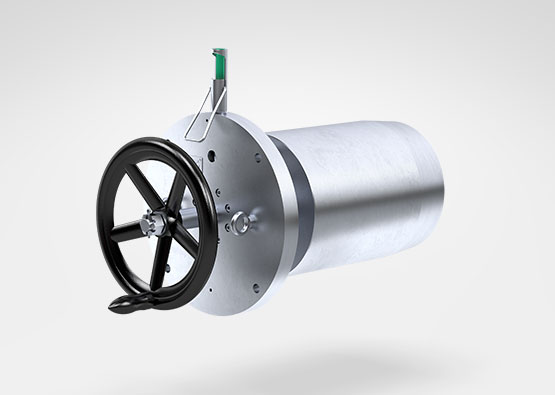

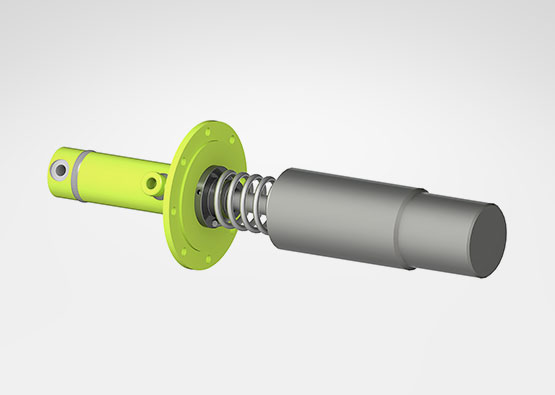

Manually activated rotor lock used for safety purposes during maintenance operations to stop the rotor mechanically. The maximum lateral force is 6400 N and the standard stroke is 95 mm. Other strokes are available upon request.

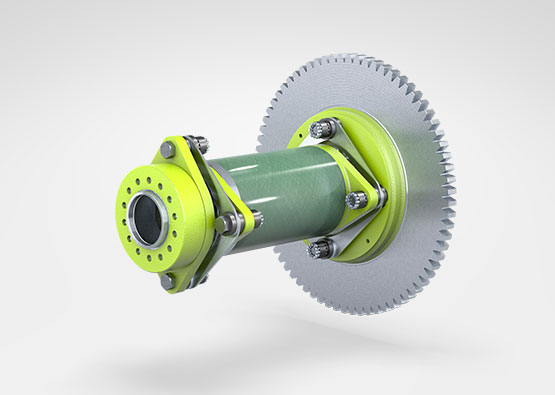

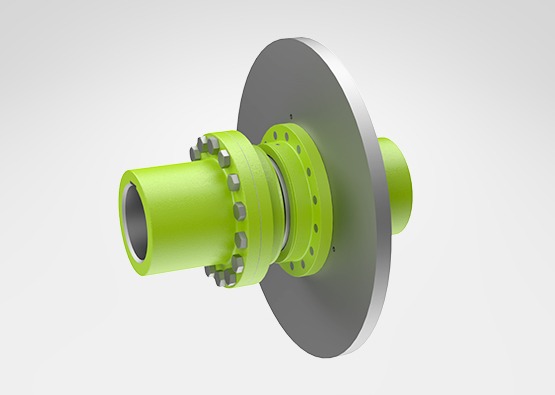

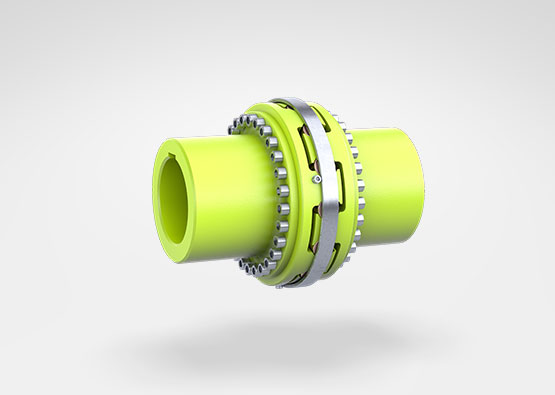

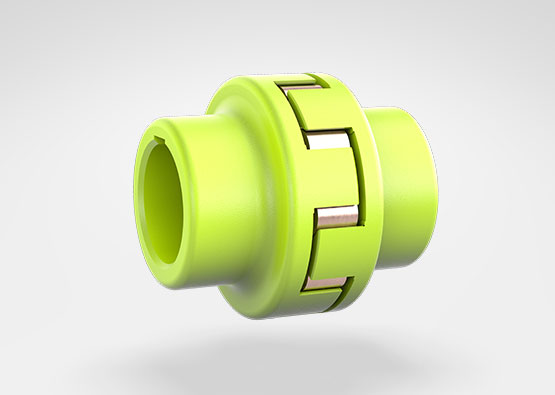

JHS WTC is a flexible disc coupling mounted between gearbox and generator. It's a tailor-made solution for wind turbine applications (Type WTC = Wind Turbine Coupling).

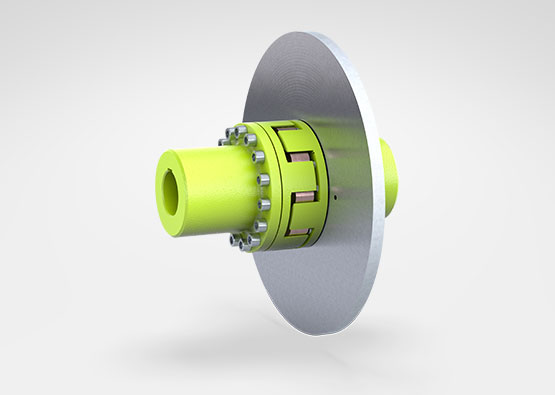

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

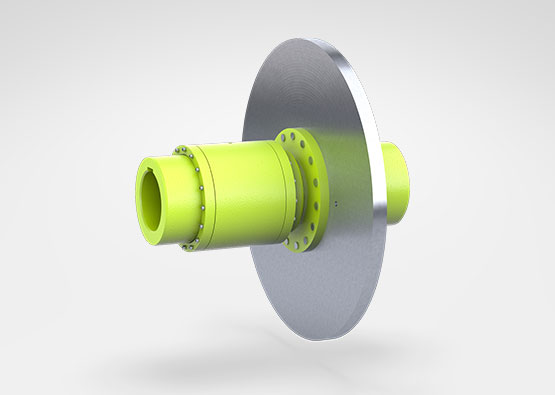

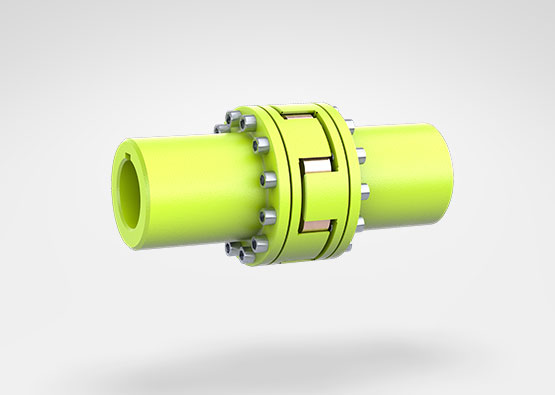

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

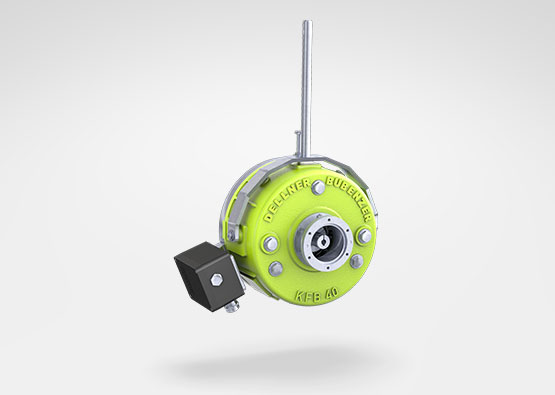

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

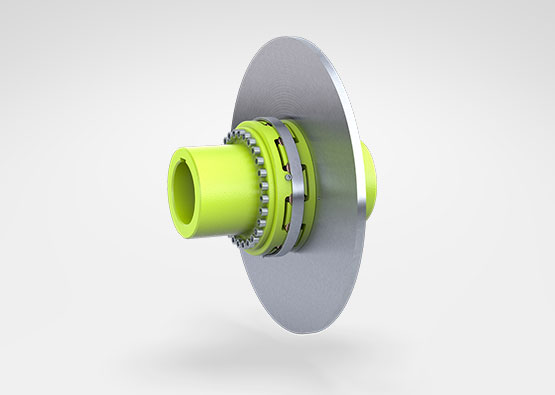

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

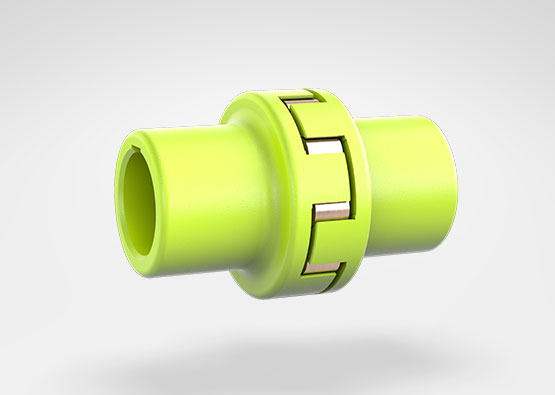

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.